Hand-Made PHD

Personal Products

Mass production is extremely efficient. It has revolutionised the manufacture of virtually everything we buy, including our food, and released a flood of affordable goods across the world. It has also changed the traditional way the maker interacts with the buyer. Now the ‘market’ is assessed, the products promising most volume are selected and made, then promotion sets out to persuade the customer that he wants what is on offer. We all know how it goes – even if you bought one last year, you need a new one now.

Outdoor gear has followed the trend. It is simply the way mass production has to work. The alternative, offering to make the customer what he wants, is simply not possible. The complications of allowing the customer free choice are crippling, the skill levels required too high, the returns from making single personal products too uninviting.

So how do PHD do it? We’ve accumulated a lot of experience in making individual outdoor gear in the fifty plus years since Peter Hutchinson started doing it on his own: it’s been a long road, but the complexities are second nature to us now and the skills are there to handle whatever comes along. We don’t set out to make every single thing you dream up, but we are offering a huge range of personal choice. Of course, the other question is why? We do it because we really believe you should get the gear you want and we get a lot of satisfaction out of doing our best to make it for you.

So how do PHD do it? We’ve accumulated a lot of experience in making individual outdoor gear in the fifty plus years since Peter Hutchinson started doing it on his own: it’s been a long road, but the complexities are second nature to us now and the skills are there to handle whatever comes along. We don’t set out to make every single thing you dream up, but we are offering a huge range of personal choice. Of course, the other question is why? We do it because we really believe you should get the gear you want and we get a lot of satisfaction out of doing our best to make it for you.

Skills

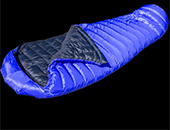

The options PHD offers to customers can create thousands of different versions of our down clothing and sleeping bags, and that’s not counting the billions of options available on our Design Your Own Sleeping Bag site and via our Custom Sized Clothing. An impossible range to stock, so each piece of gear is treated as unique to the individual who ordered it and goes through the factory on that basis from start to finish.

This way of making things demands a special set of skills. The cutters have to adapt to every option of every style which is ordered. One sewer then makes the whole item, without knowing which product and which of the myriad variations is going to land on her machine that morning. The filler in the down room hand-fills dozens of different items every day. And so on.

How is it done? The way artisans have worked for thousands of years, relying on the knowledge acquired by eye and hand and stored in the memory. It is a whole different process to ‘factory production’ as it is known in most of the world. True, we use the help of computerised patterns, specification charts, and other memory aids, but nothing can cover a fraction of the varied demands which flow in every day – except human brains and human skills. When a technical problem arises, it is nearly always solved by a person rather than by reference to a manual.

How is it done? The way artisans have worked for thousands of years, relying on the knowledge acquired by eye and hand and stored in the memory. It is a whole different process to ‘factory production’ as it is known in most of the world. True, we use the help of computerised patterns, specification charts, and other memory aids, but nothing can cover a fraction of the varied demands which flow in every day – except human brains and human skills. When a technical problem arises, it is nearly always solved by a person rather than by reference to a manual.

Quality Control

We cannot claim that our method of QC is better than anyone else’s, but it is certainly unusual. Accepted best practice is to check quality at selected stages of manufacture, not just at the end. But when the people involved are all specialists who have been making the same kind of product for years, QC becomes a continuous process. At every stage at PHD from cutting through batching, sewing, filling, and finishing, the growing product is in the experienced hands of people who will reject anything which does not come up to our standards. That’s up to five sessions of scrutiny from eyes that know what they’re looking at before it reaches the QC table.

With such a wonderful method there should be no chance of a mistake making it to final formal QC and it is in fact very rare. The occasion when a jacket went through with two left-handed pockets was a long time ago: an old joke and a useful reminder that even the best systems are not perfect.